CNC (Computer Numerical Control) machining is an important automated machining technology in modern manufacturing. By controlling the movement of machine tools through computer programs, CNC machining can achieve high-precision, high-efficiency, and complex shaped part processing. This article will provide a detailed introduction to the basic concepts, working principles, main advantages, and practical applications of CNC machining.

1、 Basic concepts of CNC machining

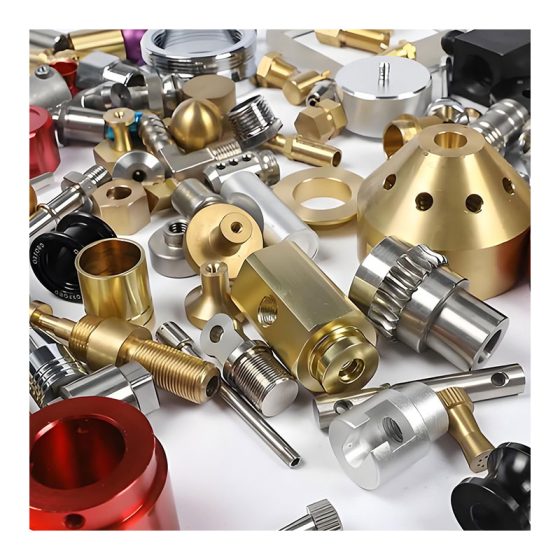

CNC machining is a technology that uses digital control systems to automatically control machine tools. By using pre written numerical control programs (such as G code and M code) to control parameters such as tool path, cutting speed, and feed rate of the machine tool, precision machining of materials such as metal, plastic, and wood can be achieved. CNC machine tools include various types such as CNC milling machines, CNC lathes, CNC grinders, etc., which can complete various machining tasks such as cutting, drilling, milling, and grinding.

2、 The working principle of CNC machining

The working principle of CNC machining can be summarized as the following steps:

1. Design and Programming

Firstly, engineers use computer-aided design (CAD) software to create a three-dimensional model of the workpiece. Then, the design model is converted into numerical control code (such as G-code) using computer-aided manufacturing (CAM) software, which contains detailed information such as machining paths and cutting parameters.

2. Data transmission

The pre written CNC program is transmitted to the control system of the CNC machine tool through data transmission interfaces such as USB, Ethernet, etc. The control system reads and interprets these codes, generates control signals, and drives various moving parts of the machine tool.

3. Processing execution

CNC machine tools automatically plan and execute tool paths based on CNC program instructions. The moving parts of the machine tool (such as the spindle, worktable, etc.) move according to a predetermined trajectory under the control of the CNC system, completing operations such as cutting, drilling, milling, etc. on the workpiece.

4. Detection and adjustment

During the machining process, the CNC system will monitor the position, cutting force, and other parameters of the tool and workpiece in real time, and make adjustments as necessary to ensure machining accuracy and quality. Some advanced CNC machine tools are also equipped with online measurement and feedback systems, which can perform real-time detection and calibration during the machining process.

3、 The main advantages of CNC machining

Compared with traditional manual machining, CNC machining has the following significant advantages:

1. High precision and consistency

CNC machining can achieve micrometer level machining accuracy, ensuring consistency for each workpiece. This is particularly important for products that require high precision and consistency, such as aerospace components and medical devices.

2. High efficiency and automation

CNC machining can operate continuously and automatically, greatly improving production efficiency. Especially in mass production, CNC machine tools can complete machining tasks without human supervision, reducing manual intervention.

The bed can be processed with multi axis linkage to achieve any complex shape processing in three-dimensional space.

3. Complex shape processing

CNC machining can easily complete the machining tasks of complex surfaces and irregular structures, while traditional manual machining is difficult to achieve such complex processes. CNC machine tools can perform multi axis linkage machining, realizing the machining of any complex shape in three-dimensional space.

4. Flexible production

CNC machining has high flexibility and can quickly adjust machining parameters and programs to meet the production needs of different batches and varieties. This makes CNC machining particularly suitable for the multi variety, small batch production mode in modern manufacturing.

4、 The practical application of CNC machining

CNC machining is widely used in various industries, and the following are several typical application examples:

1. Aerospace

The aerospace industry has extremely high requirements for the accuracy and complexity of components. CNC machining, through multi axis linkage technology, can process complex surfaces and high-precision holes, meeting the strict requirements of aviation components.

2. Automobile manufacturing

CNC machining is used in automobile manufacturing to process engine parts, body structural components, and molds. Through CNC machining, efficient mass production can be achieved, ensuring the quality and consistency of each part.

3. Medical devices

Medical devices have extremely high requirements for accuracy and surface smoothness. CNC machining can accurately process complex medical device parts, such as artificial joints, surgical instruments, and implants, ensuring high quality and reliability of products.

4. Mold manufacturing

CNC machining plays an important role in mold manufacturing. The manufacturing of molds requires high precision and complex surface shapes. CNC machine tools can ensure the high quality of molds through precision machining, thereby improving product quality and production efficiency.

5、 The Development Trend of CNC Mang

With the continuous advancement of technology, CNC machining is developing towards intelligence, networking, and flexibility. In the future, CNC machining will increasingly adopt artificial intelligence and IoT technology to achieve adaptive machining, autonomous decision-making, and remote monitoring, further improving machining efficiency and quality.

1. Intelligence

By introducing artificial intelligence technology, CNC machining can achieve automatic programming, real-time monitoring, and fault diagnosis, further enhancing the intelligence level of machining.

2. Networking

Through the industrial Internet, CNC machine tools can realize remote monitoring and collaborative work, and improve production efficiency and management level.

3. Flexibility

In the future, CNC machining will pay more attention to flexible production to meet the market’s demand for multi variety and small batch production.

epilogue