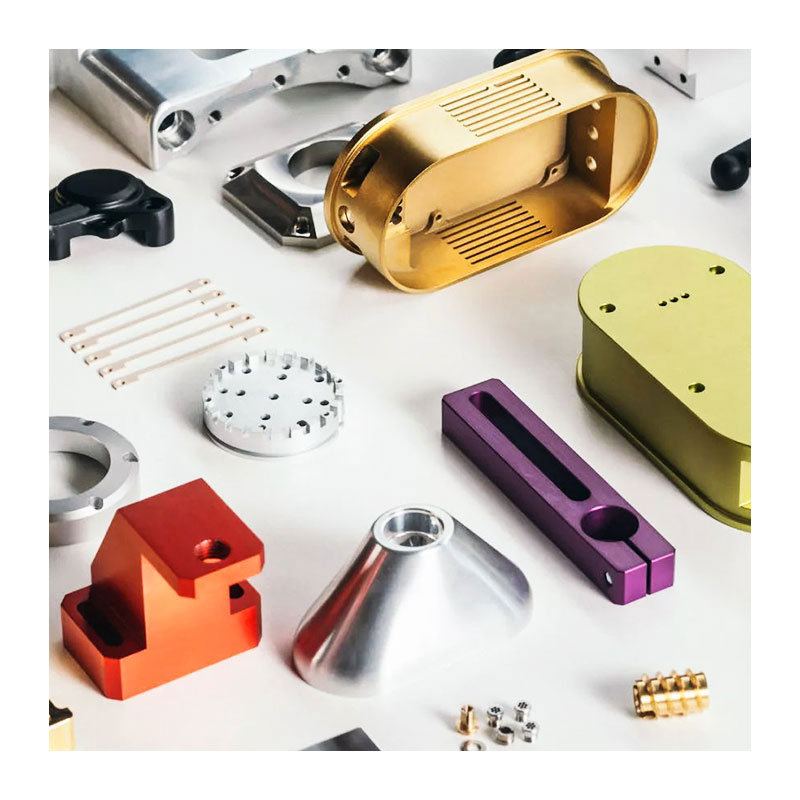

Large scale CNC machining centers have complex machining processes, multiple procedures, high requirements, and require various types of ordinary machine tools and numerous tool fixtures. They also need multiple clamping and adjustment processes to complete the machining, requiring many parts to be combined. Therefore, this article focuses on introducing the classification of parts in the machining of large CNC machining centers, hoping to be helpful to everyone.

The main objects of its processing include five categories: box type parts, complex surfaces, irregular parts, disk cover plate type parts, and special processing.

Box type parts generally refer to parts with one or more hole systems, internal cavities, and a certain proportion in the length, width, and height directions. These types of parts are commonly used in industries such as machine tools, automobiles, and aircraft manufacturing. Box type parts generally require multi station hole systems and flat machining, with high tolerance requirements, especially strict requirements for form and position tolerances. They usually go through processes such as milling, drilling, expanding, boring, reaming, countersunking, tapping, etc., requiring a large number of tools. It is difficult to process on ordinary machine tools, with a large number of tooling sets, high costs, long processing cycles, multiple clamping and alignment processes, manual measurement times, and frequent tool replacement during processing. The process is difficult to formulate, and more importantly, the accuracy is difficult to guarantee.

For CNC machining centers that process box type parts, horizontal boring and milling machining centers are generally selected for parts that require multiple rotations of the worktable angle to complete when there are multiple machining stations. When there are few processing stations and the span is not large, a vertical machining center can be selected to process from one end.

Complex surfaces play a particularly important role in the mechanical manufacturing industry, especially in the aerospace industry. It is difficult or even impossible to complete complex surfaces using ordinary machining methods. In China, the traditional method is to use precision casting, which can be imagined to have low accuracy. Complex surface components such as various impellers, guide vanes, spherical surfaces, various surface forming molds, propellers and underwater vehicle thrusters, as well as some other shapes of free-form surfaces. These types of parts can be processed using machining centers. The following are typical examples:

As a fundamental component for mechanical information storage and transmission, it is widely used in various types of automatic machinery, including disc cams with various curves, cylindrical cams, conical cams, barrel cams, end face cams, etc. For processing such parts, three-axis, four axis linkage, or five axis linkage machining centers can be selected according to the complexity of the cam.

These types of parts are commonly found in compressors for aircraft engines, expanders for oxygen production equipment, single screw air compressors, etc. For such profiles, machining centers with four or more axes can be used to complete them.

Such as injection molds, rubber molds, vacuum formed plastic molds, refrigerator foam molds, pressure casting molds, precision casting molds, etc. By using a machining center to process molds, due to the high concentration of the process, the precision machining of key components such as dynamic and static molds is basically completed in one installation, which can reduce the cumulative size error and reduce the workload of repair and maintenance. Meanwhile, the mold has strong replicability and good interchangeability. The amount of work left by mechanical processing for the fitter is minimal, and wherever the tool is accessible, mechanical processing should be used as much as possible to complete the work, so that the workload of the mold fitter mainly lies in polishing.

High-speed CNC parts, aerospace parts, medical machinery parts, core-moving machine-CNC lathe parts processing

High-speed CNC parts, aerospace parts, medical machinery parts, core-moving machine-CNC lathe parts processing